When people think about solar panels, they usually imagine the shiny glass, the blue cells, or maybe the big frames lined up in a solar farm. But the truth is that the long-term performance of a solar panel depends heavily on something most people never even see: encapsulation.

If you are wondering about solar cell encapsulation, you can think of it as the invisible shield that keeps a solar panel alive for 25–30 years. And guess what? Without strong solar PV module encapsulation, even the best solar cells won’t survive India’s heat, dust, humidity, rains, or pollution.

So today, let’s break this down in the simplest way possible: what encapsulation is, why it matters, how it affects energy output, and how choosing the right solar cell encapsulation materials directly improves the quality of your solar PV system.

Without any further ado, let’s get into it!

Understanding Solar PV Module Encapsulation

Let’s start from the basics.

In the simplest words, what is solar cell encapsulation?

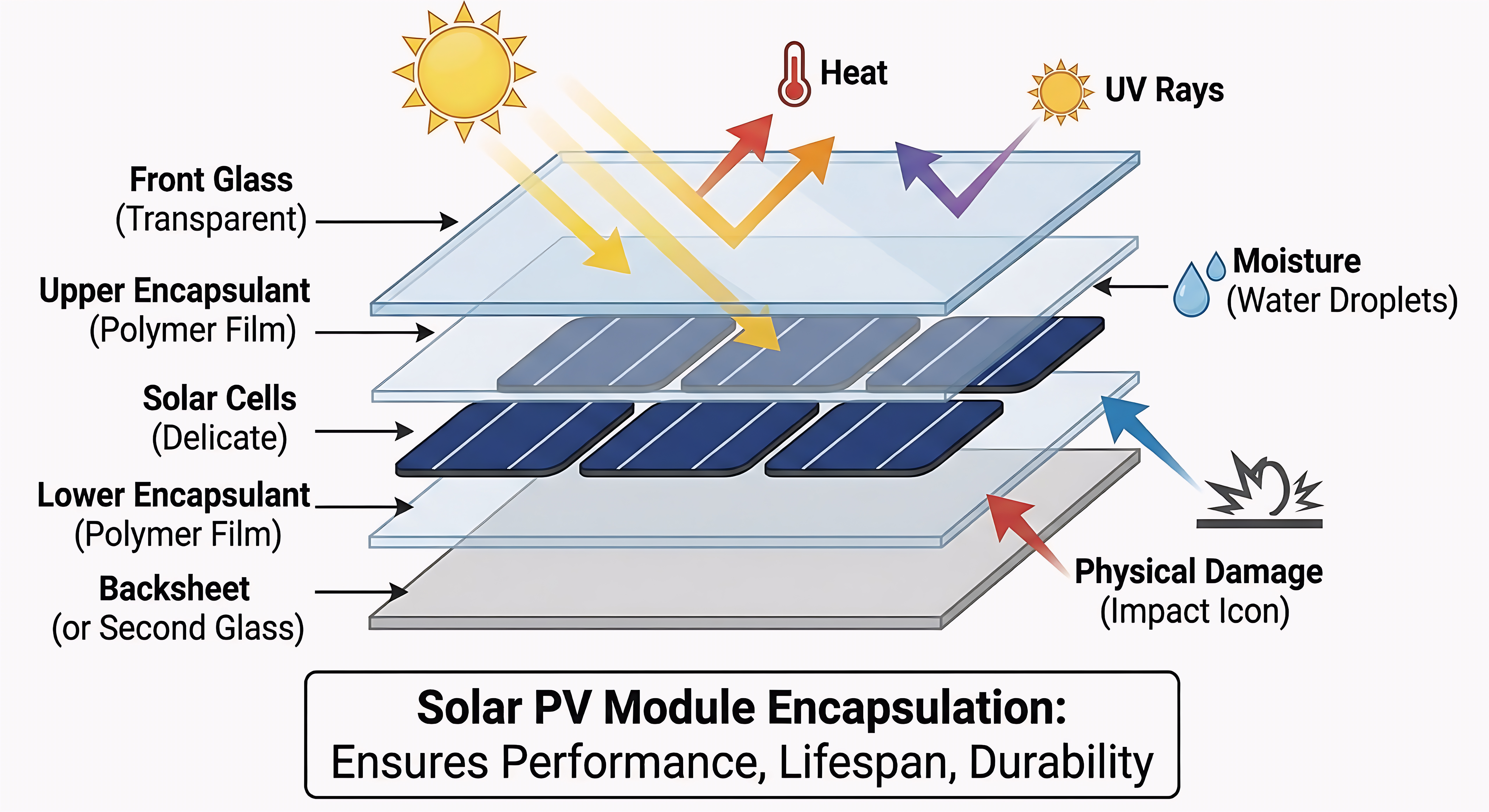

It is the protective process of sealing delicate solar cells between special polymer films to keep them safe from heat, UV rays, moisture, and physical damage. The layers we are talking about sit between the front glass and the backsheet (or second glass) at the rear. Their job? Well, it is very simple yet extremely important:

Hold the cells in place

Protect them from the environment

Maintain transparency so sunlight can reach the cells

Stop water, dust, and air from entering

Now, this whole protective sandwich is what we call solar PV module encapsulation. And guess what? It literally affects everything, such as performance, lifespan, durability, and even warranty claims.

We know that you’ll mostly hear about:

EVA (Ethylene Vinyl Acetate) is most commonly used.

Then there is POE (Polyolefin Elastomer), which, no doubt, is great for humidity-prone areas.

EPE (EVA+POE+EVA) is commonly used for TOPCon application

TPT/TPE films are another one, and,

Silicones (in some special applications)

Just so you know, all of these actually fall under the broad category of solar cell encapsulation materials. And choosing the right one matters a LOT. For example, we know how EVA is the most popular one, but POE is the one rising fast because it prevents degradation better in high-heat and coastal regions.

So yes, encapsulation may sound boring, but trust us, it’s one of the biggest reasons a solar panel survives decades.

Why Encapsulation Is Critical for Module Quality

If you have ever wondered why some solar panels keep performing flawlessly for literally decades, while others begin to lose their power much earlier, the answer often lies in just one thing: the quality of solar PV module encapsulation. Yes, it may be hidden inside the panel, but well, its impact is another, but invisible. It is the layer that takes the daily beating from the environment, so your solar cells don't have to.

So quiet, literally, a good solar cell encapsulation acts almost like a bodyguard. Basically, everything that could slowly damage your panel from the inside is now being protected. And if in case this layer is not strong, the panel may look just fine to you, but deep inside, the degradation starts creeping in.

And because encapsulation plays such a big role in power retention, safety, and longevity, it directly decides the overall quality of your solar PV module.

When solar PV module encapsulation is done right, the difference is remarkable and would agree with it too. Even if you cannot see it with your eyes! Strong, high-grade solar cell encapsulation materials stay clear and make sure that sunlight actually reaches the solar cells, which means more electricity for you.

What else does it do?

Reduces hotspots

Prevents microcracks from spreading

Keeps the electrical pathways protected

All these actually result in a solar PV module that:

operates at a higher efficiency

holds on to its performance for longer

gives you a much better return on your investment

So overall, this is a long-term performance booster, which not only protects but also helps your panel to perform better over the years.

Also Read : Key Features to Look for When Buying Solar PV Modules

Challenges and Risks in Encapsulation

Of course, nothing is ever so easy as it sounds. There are challenges as well, which manufacturers have to watch out for. Some of the common risks include:

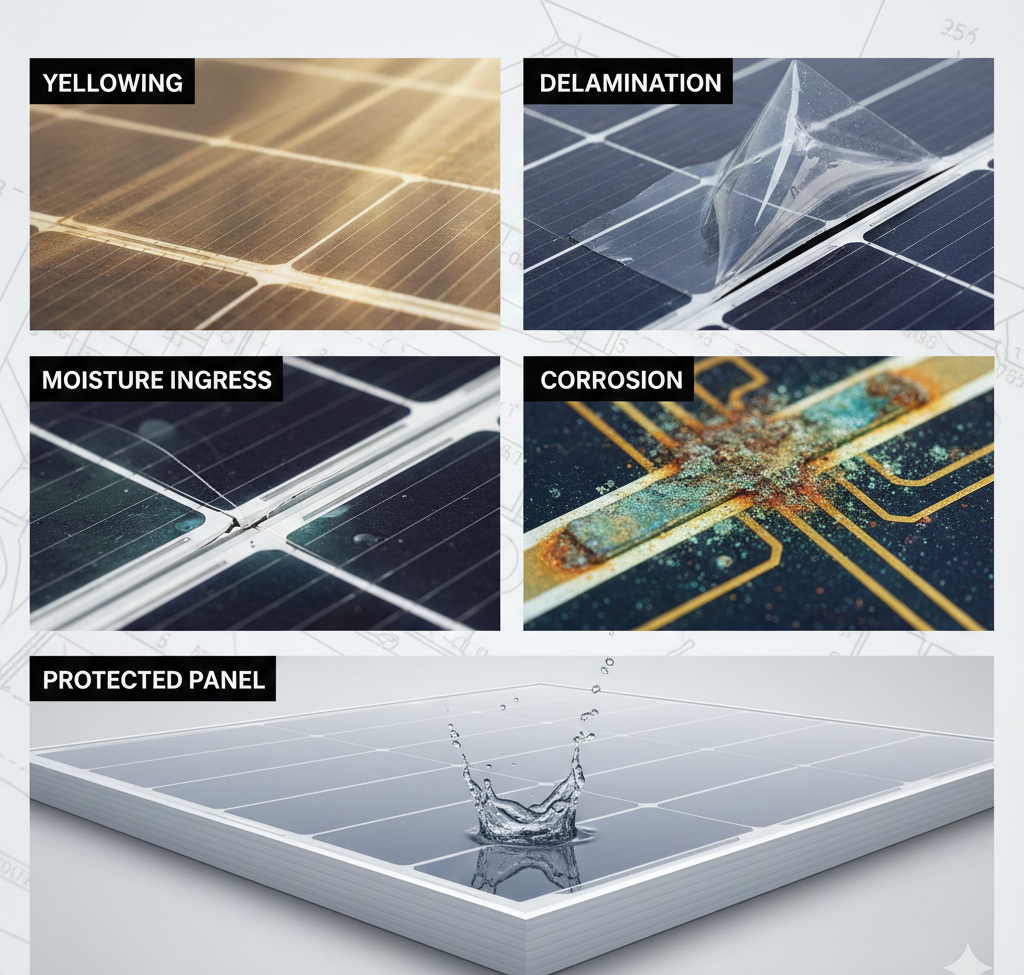

Yellowing

This is obviously a visible issue, and can happen over time due to UV exposure. The more the layer yellows, the less the light reaches the solar panel. So yellowing should not happen!

Delamination

Delamination is when layers of the panel start peeling away from each other. It's literally the silent killer. And once it happens, moisture will enter, air pockets will form, and the panel can degrade.

Moisture ingress

Talking of moisture, it is one of the biggest enemies of solar panels. Even a tiny amount that finds its way inside can corrode connectors, damage cells, and lower the efficiency. This is why, go for trusted manufacturers like Emmvee PV who use the right solar cell encapsulation modules. This way, it has a seal that keeps the water out for decades.

Corrosion

When moisture combines with oxygen inside the panel, corrosion begins. It will slowly eat away the metal parts, and well, electricity won’t be the same for you ever again. This is long-term damage and needs to be managed before it even starts.

Here is a quick comparison table of EVA, POE and EPE Encapsulants:

This table literally shows why choosing the right solar cell encapsulation materials is not just a “technical detail,” but a long-term quality decision.

Final Thoughts

You now understand what most people never think about! It is the hidden layers inside a solar panel that actually decide how long it will survive and how much power it will generate. When you look at a solar panel, all you see is the glass, the frame, and maybe even the shimmer of the cells. But what actually protects these cells day after day, though, are summers that cross 45°C, monsoons that drench everything in sight, dust storms, pollution, and years of constant sunlight, is encapsulation.

It is truly one of those things you don’t appreciate until it fails. Because when encapsulation goes wrong, it doesn’t scream for attention. It quietly eats away at your power output. So it literally happens like, a little drop this month, a little more next month, until suddenly one day you realize, “Wait… this panel isn’t performing the way it used to.”

This is why you need a good solar PV encapsulation and how it actually makes a difference between a panel that works beautifully for 25 years and a panel that dies in 7 years. So there is no doubt that solar panels are a long-term investment. Not a one-year gadget, not a seasonal trend, but something you rely on every day, for decades.